- Work preparation

- Crowns and Bridges

- Model casting

- Duplication technique

- Equipment and Instruments

- molding TECHNIQUE

- Ceramic TECHNIQUE

- Total and partial dentures

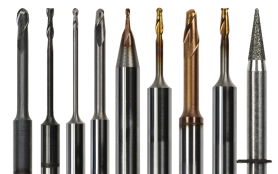

- CAD/CAM - Digital Line

- Excellence Line

- Catalog

![]() Languages

Languages

YETI digi MILL - cooling lubricant for Wet option

20,00 EUR - 95,00 EUR

add. 19 % VAT excl. shipping costs

Login